Reasons & Factors of silicone rubber wire breakdown

There are many reasons and factors for silicone rubber to be broken down, which boil down to the following conditions

1) External injury . From the analysis of the operation of the industry in recent years, a proportionate number of silicone rubber low-temperature cable failures are caused by mechanical damage. For example: when the silicone rubber low-temperature cable laying device is not standard construction , it is easy to form mechanical damage. Sometimes if the damage is not significant , it will take several months or even years to cause a complete breakdown of the damage part to form a fault , and sometimes a short circuit fault will occur in the short term if the damage is significant, indirectly affecting the operation of the equipment and the safe consumption of the electricity unit.

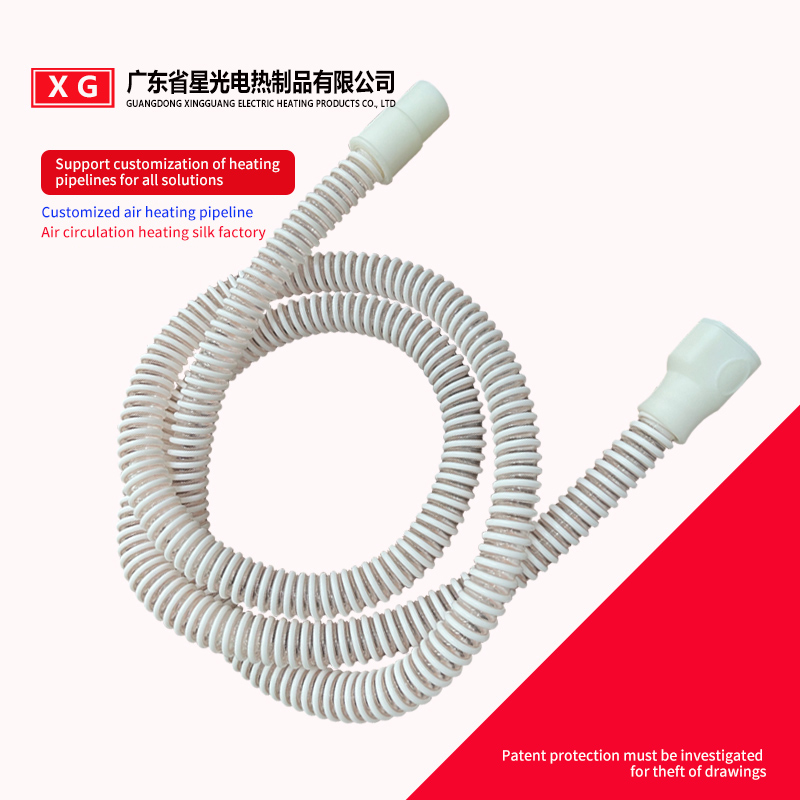

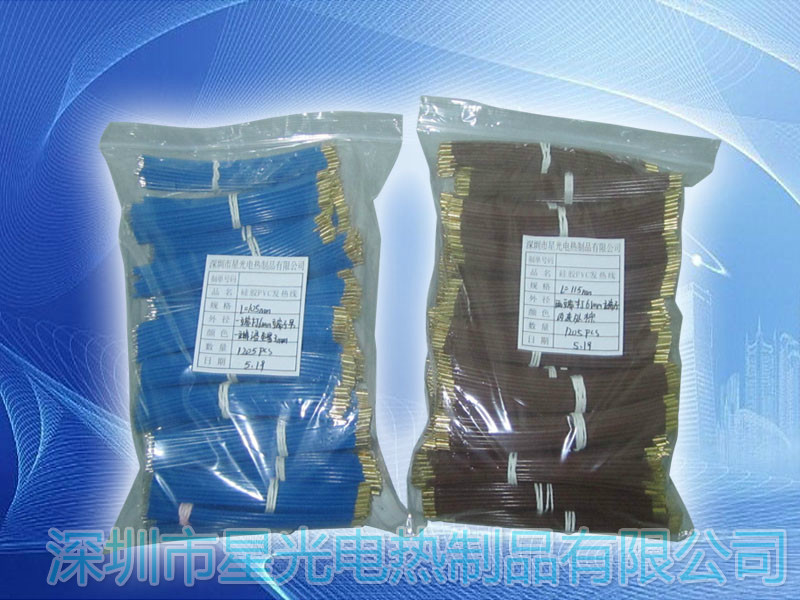

Guangdong Xingguang Electric Heating Products Co., LTD(love715.cn ) is an production & sales of silicone rubber high voltage wire , silicone rubber high temperature wire, Teflon high temperature line in one of the enterprises.

2) Insulation damp. This situation is also rare in silicone rubber low-temperature cables , and individual episodes occur at flat cable joints in directly buried or row tubes . For example: the manufacture of silicone rubber low-temperature cable joints fails and the silicone rubber low-temperature cable joints are made under wet meteorological conditions, which will make the joints enter water or mix with water vapor, and the formation of water branches under the action of electric field over a long time will gradually damage the insulation strength of silicone rubber low-temperature cable and form a fault